PRACTICALLY SPEAKING -How and Where to focus improvement initiatives in the Machine Shop

During a career spanning nearly 40 years, I have worked in--and

visited--many machine shops. These ranged from small subcontractors to valve OEMs

(Original Equipment Manufacturers) and commercial aircraft manufacturers. Everyone is looking to improve their

operations. Those who aren’t are either going out of business or already out of

business. The real question is how and where does one start?

During a career spanning nearly 40 years, I have worked in--and

visited--many machine shops. These ranged from small subcontractors to valve OEMs

(Original Equipment Manufacturers) and commercial aircraft manufacturers. Everyone is looking to improve their

operations. Those who aren’t are either going out of business or already out of

business. The real question is how and where does one start?

Follow a simple

3-step process.

Step 1: Focus. Trying

to fix everything all at once will ensure that there will lots of effort

expended with little return in either the short- or medium-term. Start by

focusing on known bottlenecks. These are usually best identified via regular

walks through the value stream (known as a GEMBA walk) and by simply asking

employees about trouble spots. A few machines almost always have piles of work

in front of them while the work at other machines ebbs and flows.

Step 2: Gather data. This

can be done manually in the short-term quite easily. It may involve little more

than dutifully recording key information on a chart kept close to the equipment

and entering the data into a spreadsheet for analysis. There are even sample

data collection forms available online that could be tailored to your specific

needs. For firms planning on implementing an IIoT (Industrial Internet of

Things) strategy, just a few machines can serve as a proof-of-concept or pilot

project before investing heavily in a technology solution. Some solution

providers, such as Forcam GmbH (www.forcam.com) and 42Q (www.42-q.com),

have start-up packages to get automated data collection installed and working quickly

on a handful of machines.

Whether collecting data manually, or through a software application,

operators will have to input some of the reasons for, and frequencies of,

events that occur. To facilitate this, predefine some standardized reason codes for items related

unplanned downtime, low performance and impacts on quality.

These can be modified along the way based on the frequency of occurrence.

Step 3: Analysis.

Analyse the data to determine a course of action. Standard techniques, such as

histograms and Pareto analysis, will go a long way to being able to see the top

few reasons for not achieving goals in one aspect or another.

Don’t jump to

conclusions

I had an experience where there was a big emphasis from

executive management to focus on operator performance to standard time. Fortunately,

I was able to hold off and wait for the results of an initial period of data

collection. The analysis showed that although standard times could be improved,

the BIGGEST improvements were to be found simply in keeping the machine running

(productively). Without the data, we would have been going down the wrong path.

By the numbers

Bring this all together by using OEE (Overall Equipment

Effectiveness) in a judicious manner. OEE is comprised of three separate

components:

Availability – a comparison of the scheduled operating time

that the equipment is actually operating

Performance – a comparison of the speed at which the

equipment is operating versus the speed at which it is designed to operate

Quality – the ratio of good parts produced to total parts

produced

OEE = Availability x Performance x Quality

A worked example of the calculation is shown in the attached

image. The boxes highlighted in blue represent the data that users must collect

and enter. The rest is calculated by formula. Beyond these figures, operators

must be recording reasons and frequencies relating to key events (see step 2

above).

People use Availability, Performance, and Quality as second

level indicators of where to focus improvement efforts or to determine where to

collect more, or more detailed, data for further analysis. These metrics can

guide us toward the right approach, whether it be to implement SMED (Single

Minute Exchange of Die), 5S, or Kaizen to name a few of the key lean approaches

available.

Companies should also look at TEEP (Total Effective

Equipment Performance) because it introduces the concept of Loading to the

equation. Loading is the percentage of calendar time that equipment is

scheduled to run. From total of 7 days of 24 hours in a week, we need to subtract

planned non-working days, non-working shifts within a workday, and scheduled

maintenance. This comes together with OEE as per the formula:

TEEP = Loading x OEE

Significant improvement in TEEP and OEE can come quickly by

working with employees and supervision to add shifts, stagger breaks, implement

TPM (Total Preventive Maintenance), and other approaches.

TAKEAWAYS: Use

data to drive decision-making. Look first for the low-hanging fruit. Don’t

chase the metric to the exclusion of good practice.

NOTE: A version of this article was published in Valve World Magazine 2018-09

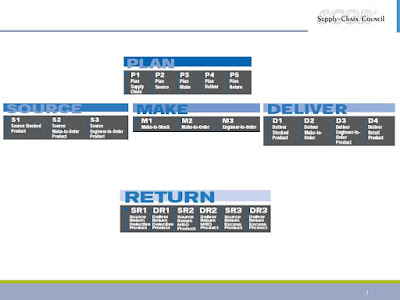

About FarStar: FarStar is boutique consulting firm with a focus supply chain transformation, of which a key lever is Sales & Operations Planning. With team members located in Canada and the US, the company has extensive experience across a wide range of industries including aerospace, defence, high-tech/electronics, and industrial products in a variety of business environments, ranging from make-to-stock to engineer-to-order.

Comments

Post a Comment